Hydrogen Powered Propulsion for an Offshore Crane Vessel

A technical, environmental and economical evaluation from a shipowner’s perspective by Gilles Hagen

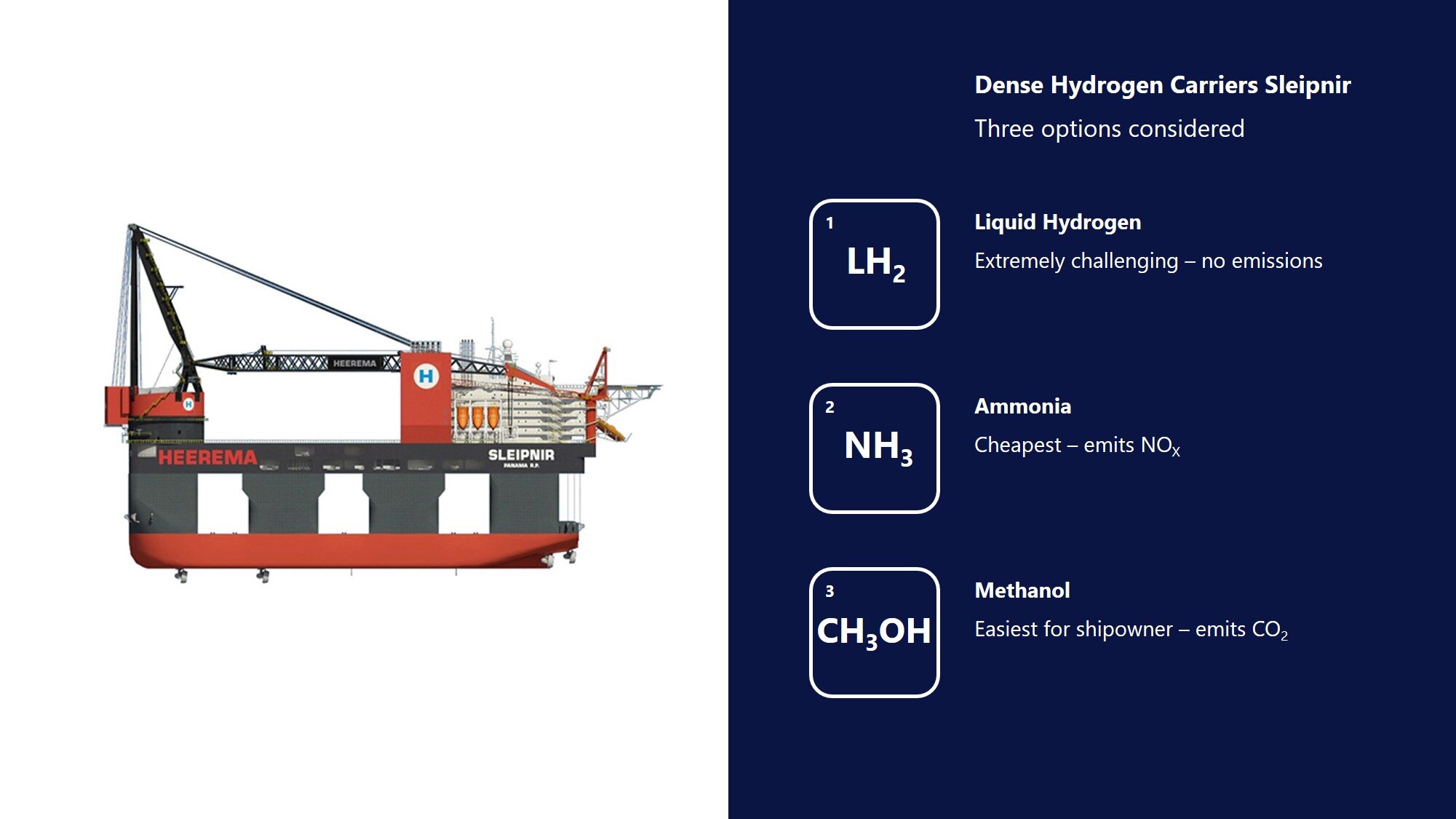

Summary - This thesis performs a technical, economical and environmental feasibility study of dense hydrogen carriers as a fuel to power the largest semi-submersible offshore crane vessel in the world – Heerema’s Sleipnir. Three options are identified as feasible hydrogen carriers: liquid hydrogen (1), ammonia (2) and methanol (3). Given the boundary conditions of this thesis, an ammonia-fueled drive train with hydrogen co-combustion is the most preferred method to power the Sleipnir. This drive train is the most cost-effective solution and poses the least amount of technical challenges.

The below gallery is a graphic overview of the main results of the study. The subsequent paragraphs of this blog highlight the findings of the study in more detail, including elaboration on the drive trains, the main findings in terms of economics, conclusions to the research questions and finally the main assumptions used. Before we can elaborate however, we need to answer one question first. Why bother with hydrogen in the first place?

The maritime industry is facing a great challenge

Ship emissions need to be reduced significantly. The International Maritime Organization (IMO) is striving for at least 50% reduction of greenhouse gasses by 2050. For some, this is not enough. The US is now calling for shipping to have zero emissions by 2050. Such a call might be supported by many (Western) countries and organizations, but is unpopular for many other members of the IMO. Nonetheless - whether it is a 50% or a 100% reduction - the challenge remains almost daunting and will completely transform the maritime industry. One prominent player in the industry is paving the way in this transformation - Heerema.

> Why Heerema is facing the challenge head on

Heerema is a world-leading marine contractor that operates in the oil, gas and renewable energy industry. They own a fleet of offshore construction vessels, including the worlds largest and second-largest semi-submersible crane vessel Sleipnir and Thialf. In 2020, Heerema implemented a Carbon Neutral Roadmap, which made them the first carbon neutral marine contractor in the world. That is mostly achieved by means of purchasing carbon credits at the moment, but they aim to do more.

The Carbon Neutral Roadmap has been put in place to fully prevent, reduce and if needed compensate all CO2 emissions by 2025. A wide range of projects is currently being executed to decrease Heerema’s carbon footprint. A prime example of this is that Sleipnir is mainly sailing on LNG instead of conventional MGO. LNG has a low sulphur content, better hydrogen-to-carbon ratio and emits less NOx during combustion. Despite it being considered a cleaner fuel, it is still a fossil fuel however. That is why Heerema is looking into alternative fuels as well, one of them being hydrogen.

> Why hydrogen can help Heerema (and others)

Hydrogen is considered by many in the industry as a clean alternative to existing marine fuels. But how many shipowners have actually performed a techno-economic analyses for hydrogen of their vessels? Heerema is paving the way and has taken the largest crane vessel in the world - Sleipnir - as a case study. The study performed by Gilles Hagen aims to determine the most preferred way to drive a semi-submersible offshore crane vessel with hydrogen from a shipowner’s perspective.

It is not only Heerema who acknowledges that hydrogen might play a big roll in the future for powering their vessel. Heerema’s customers are also becoming increasingly motivated to do so. Companies such as Ørsted and Equinor have set ambitious targets to be CO2 neutral by 2040 and 2050. Within this ambition, they are demanding the companies within their supply chains to set the same targets. This creates a commercial incentive to look for alternative propulsion systems with renewable fuels. Hydrogen sounds promising in this regard, but poses serious technical, environmental and commercial challenges.

> Why Heerema looks into liquid hydrogen, ammonia and methanol

85% of all the hydrogen in the world is produced and consumed on-site, which is why long-term storage was never a big focus on innovation. This becomes an issue when it is applied to ships, as it would need to be stored for weeks or months on end. Because hydrogen gas is the lightest gas in existence, this raises some serious technical challenges.

If it were to be stored under ambient pressure, the fuel tank would need to be approximately 200 times larger to store the same amount of energy compared to LNG. Obviously, this is not possible on a vessel as space is a limiting factor. As a result, the storing conditions of hydrogen need to be changed. That is why the research performed by Gilles Hagen is looking into other methods of storing hydrogen. Grossly speaking there are two ways of doing so.

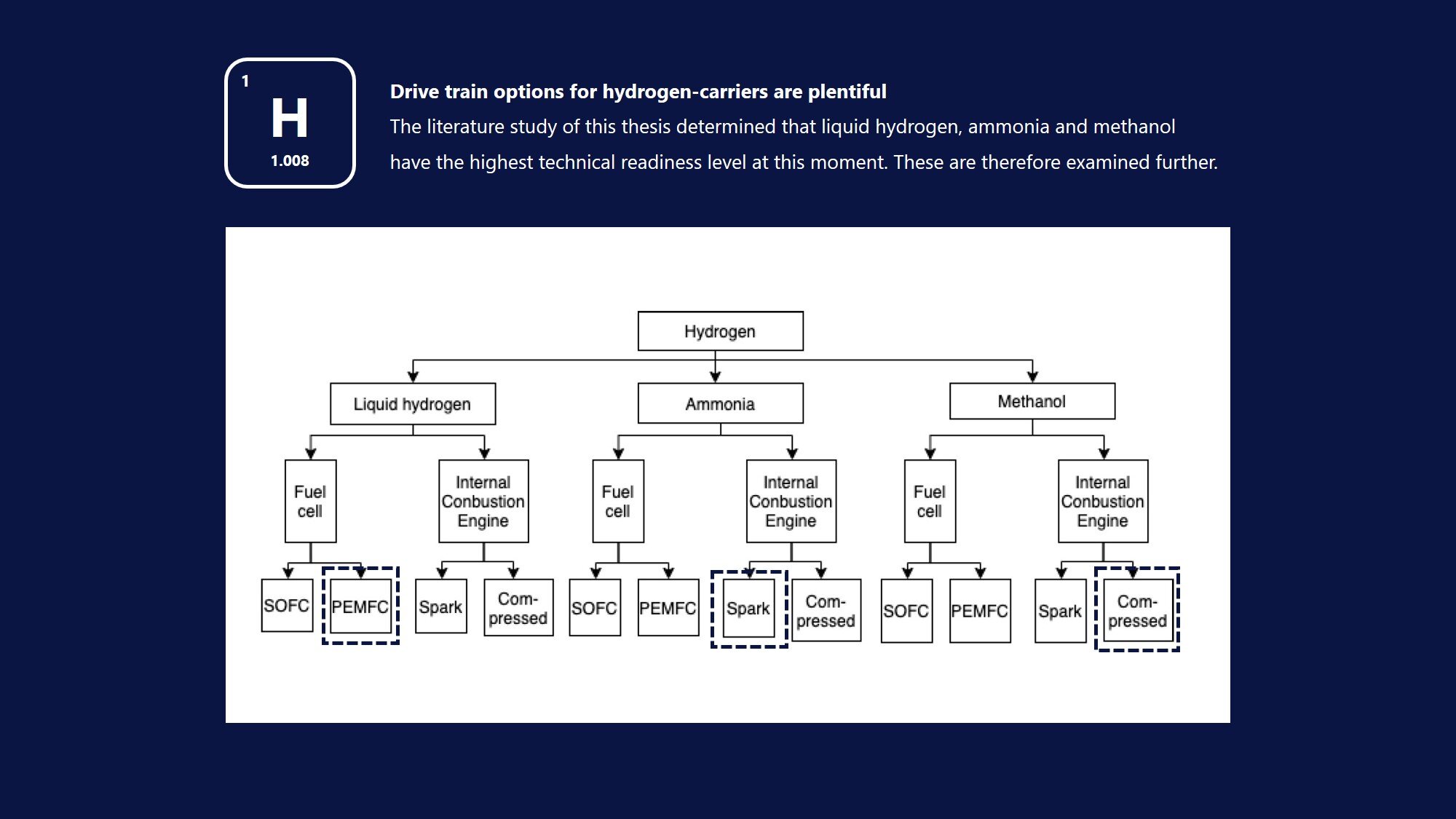

The first is to compress or cool the hydrogen. For example, hydrogen can be stored under a pressure of 700 bars, which is done for hydrogen automobiles. Or hydrogen can be cooled to -253 °C, at which point it becomes liquid. The hydrogen can then be led through a fuel cell to generate electricity. More information about the properties of hydrogen and fuel cells can be found on the insights section of Mr. Sustainability.

The second method is to chemically bind the hydrogen to a so called carrier. Which carrier would be best suited to chemically bind hydrogen is a much debated topic. For the maritime industry however, ammonia and methanol seem to be favoured as these are already widely available and used in many other chemical process. The hydrogen carrier can then be combusted in ‘regular’ engines, or in some cases used in fuel cells.

For this research, both these options for a drive train are investigated and their potential is applied to the largest crane vessel in the world, Sleipnir.

Technical Evaluation - Drive Train Configurations

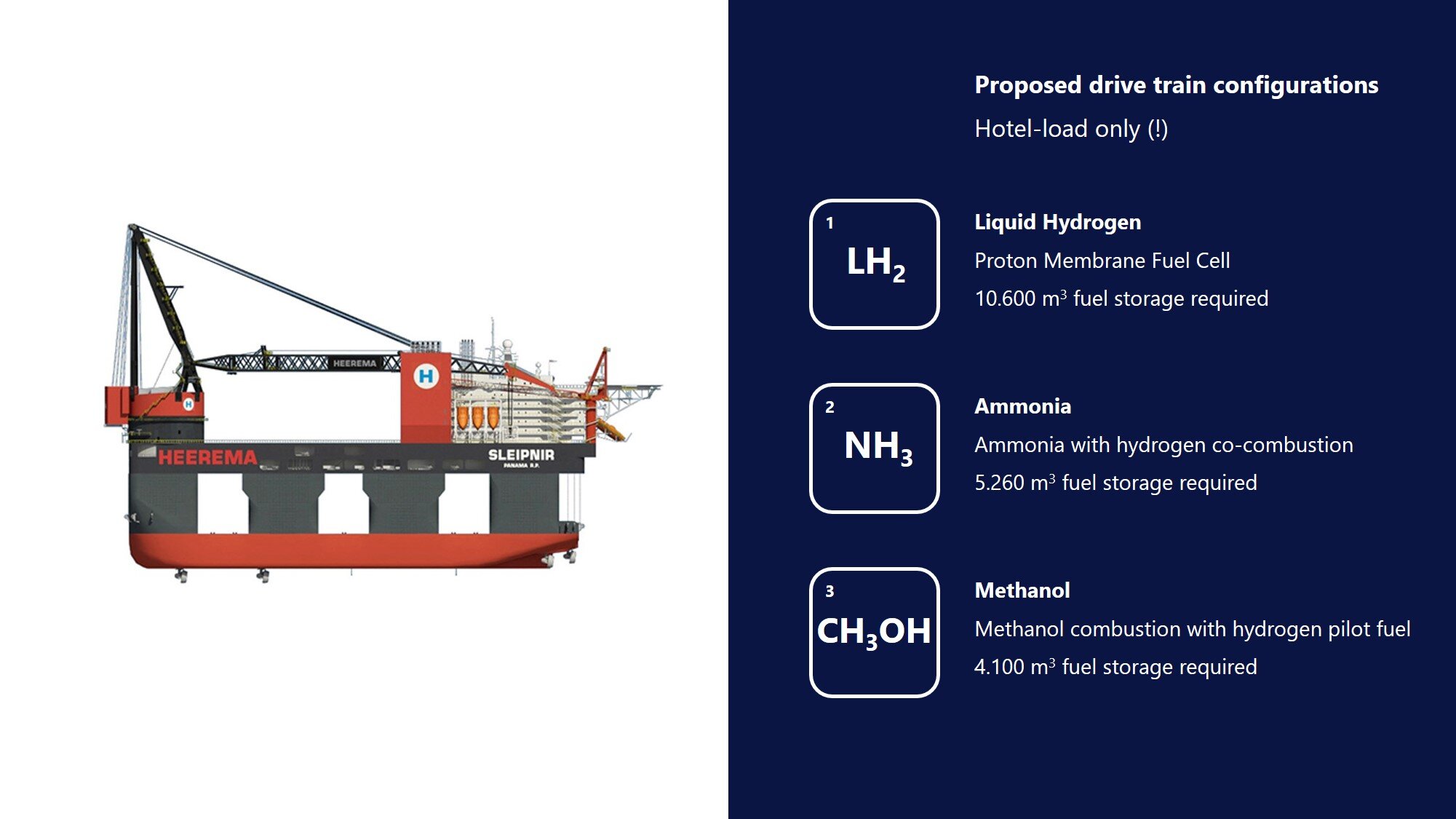

The study aims to determine which hydrogen powered propulsion for an offshore crane vessel is most suitable from a shipowner’s perspective. This assumption automatically limits the amount of drive trains considered, as some are deemed undesirable from an operational (shipowner’s) perspective. Furthermore, the drive trains are all designed to provide so called hotel load for the vessel only. For Sleipnir, it is assumed that 6.5MW has to be continuously provided by each drive train. More assumptions on the drive trains, hydrogen carriers and others can be found at the end of this blog.

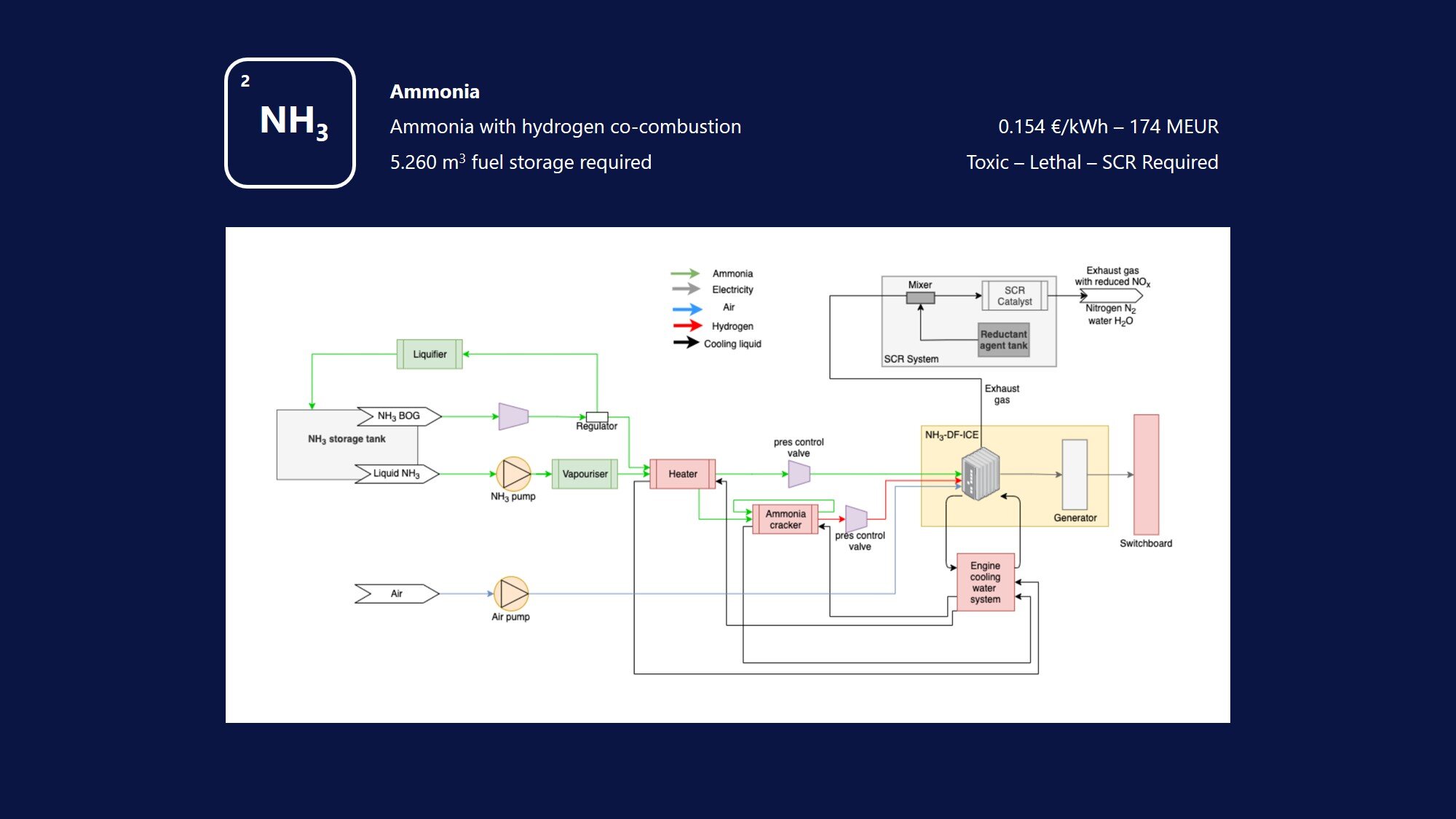

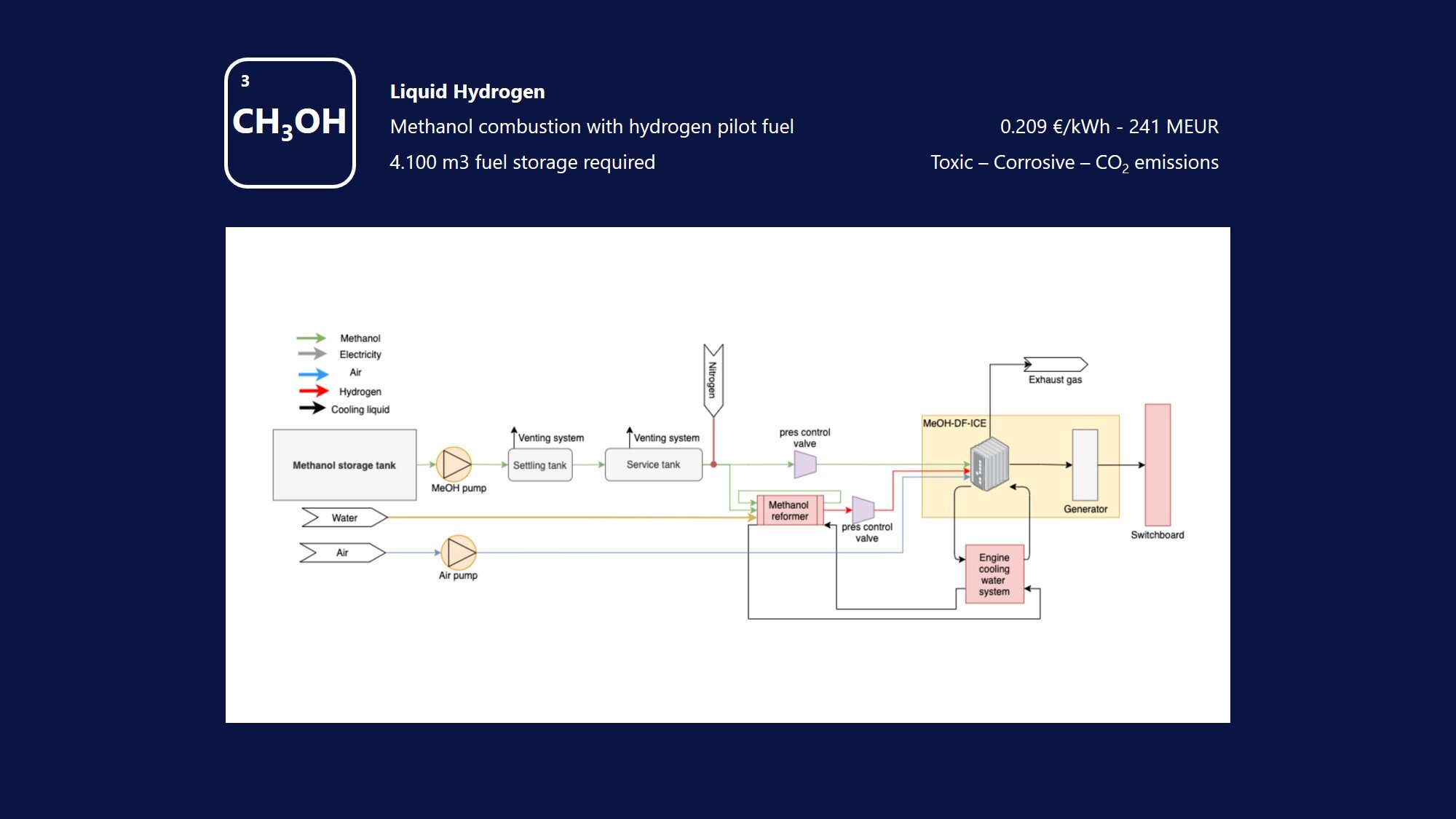

Given these assumptions, three distinct drive trains are considered and evaluated on technical feasibility. These are the liquid hydrogen fuel cell drive train - option 1 - the ammonia co-combustion drive train - option 2 - and the methanol combustion drive train - option 3. All options are considered technically feasible, but require retrofitting the storage tanks and piping, overhauling engines and installation of new equipment. This includes but is not limited to reformers, crackers, vaporizers and battery systems.

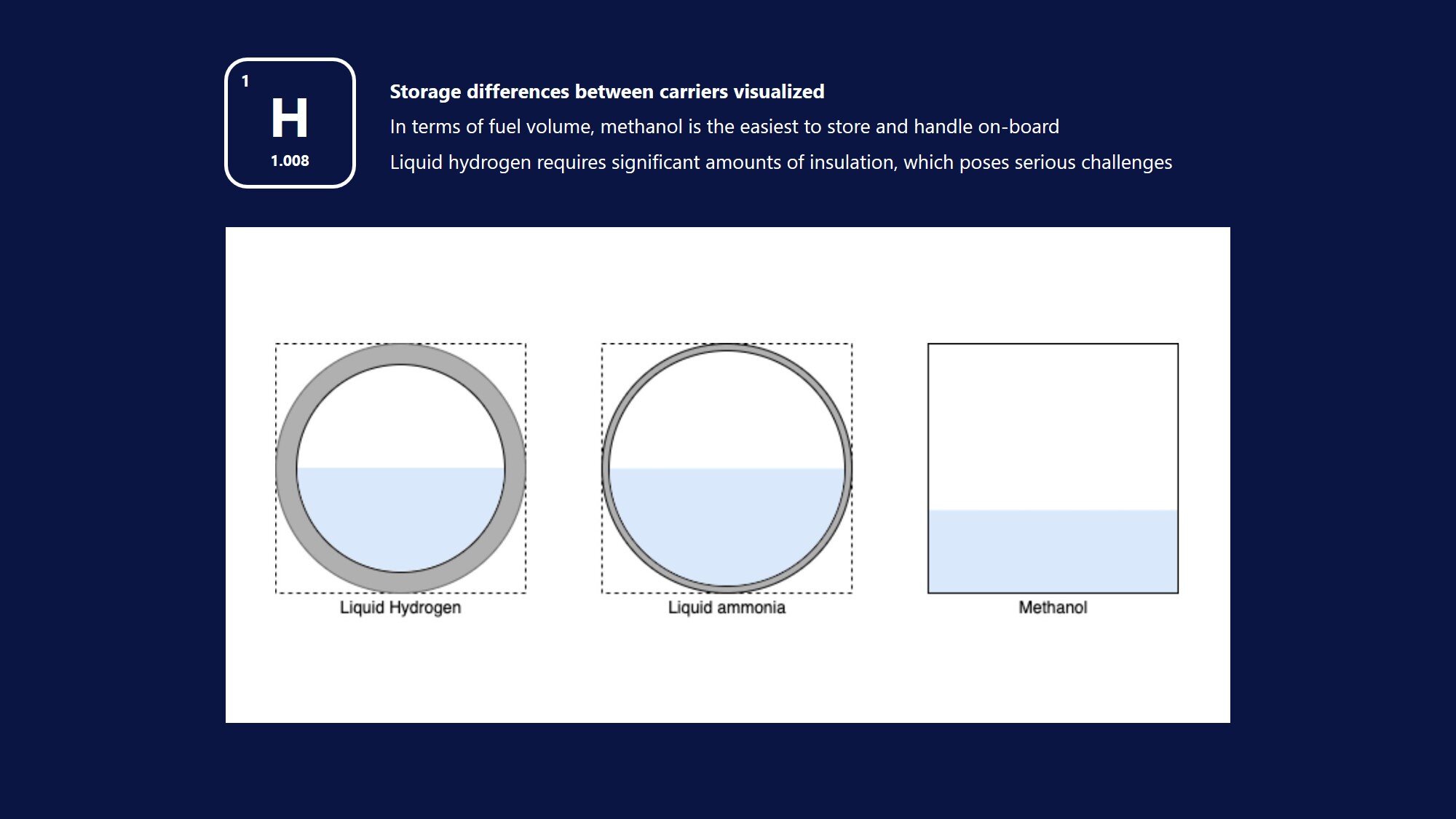

In terms of storage required, liquid hydrogen requires the most volume at 10.600 m3. Ammonia and methanol require 5.260 m3 and 4.100 m3 respectively. All these options require storage volumes on top of existing LNG and MGO storage. Storage space requirements (for liquid hydrogen in particular) thus impose serious operational limitations and is considered as the largest technical challenge that is to be resolved. More details on the different drive trains options are provided below.

> Liquid Hydrogen

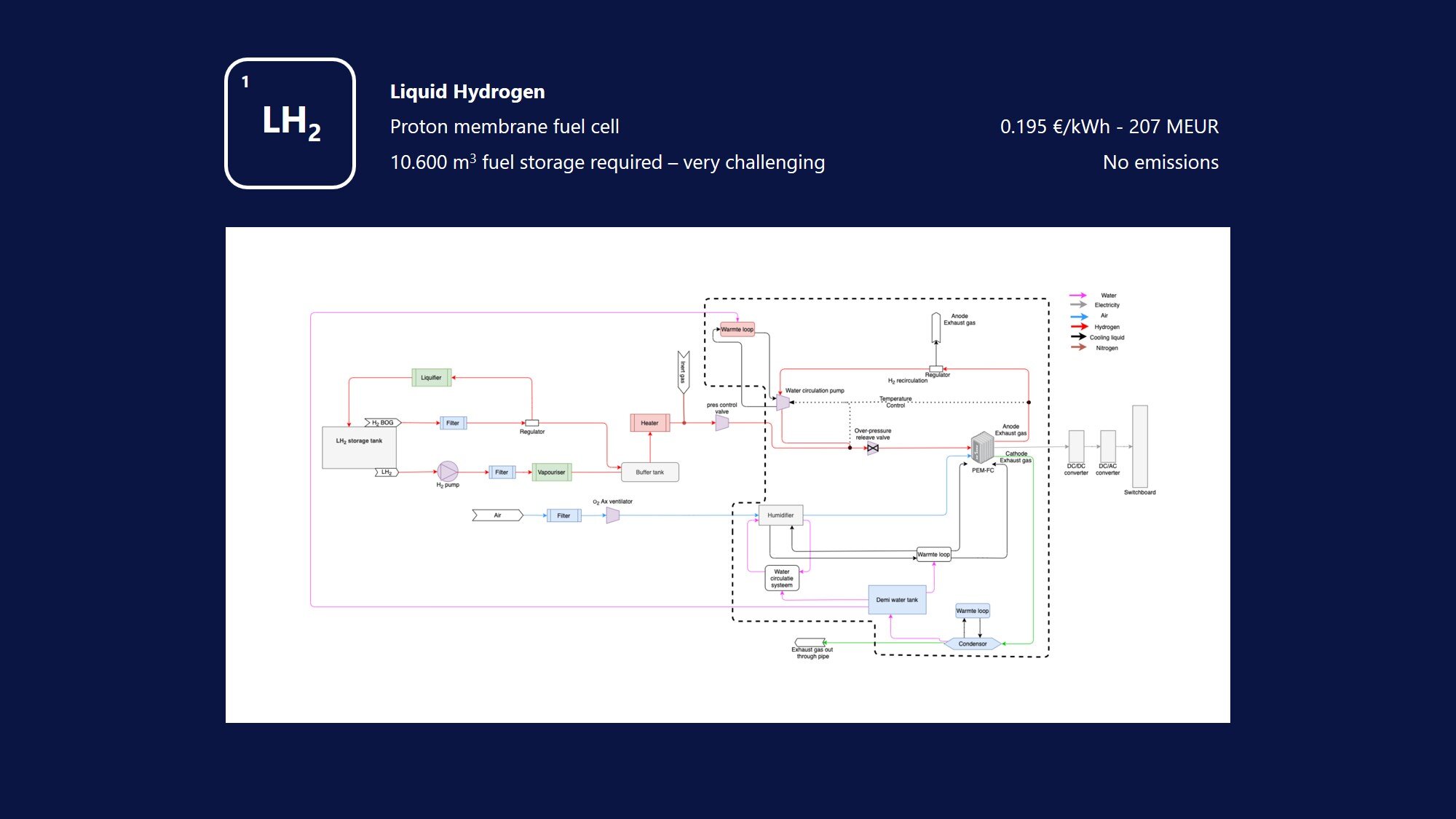

Option 1 is a drive-train that powers the vessel using liquid hydrogen in an proton exchange mem-brane fuel cell. This drive-train design is mostly dominated by the regulations for gas fuelled ship installations and fuel cell installations. The proposed overall system has a theoretical on-board efficiency of 44%. As with all the other options, it is only able to provide hotel-load. The volumetric energy density of liquid hydrogen is more than twice as small as that of LNG, which will result in a fuel tank approximately twice as large to store the same amount of energy. This configuration consumes 7.300 m3 of hydrogen per fuelling cycle, but up to 30% of the hydrogen needs to remain in the fuel tank, resulting in a total tank capacity of 10.600 m3. At the time of writing, NASA has the largest LH2 storage tank in the world with a volume of 3.800m3. Additionally the hydrogen needs to be of very high grade purity. ISO 14687-2 specifies that hydrogen for fuel cells is to be 99.97% pure, which is almost ten times more than needed for hydrogen combustion (99.9%). Hydrogen requires at least 20% more energy to produce compared to LNG, ammonia and methanol due to the energy required for liquefaction.

Storage - The total required storage volume is approximately 10.600 m3 to ensure 7 weeks of operation.

Drive train details - The PemGen MT-FCPP-500 from Nedstack is chosen as modular fuel cell, of which a total of 60 are installed. Before liquid hydrogen enters the fuel cell however, it needs to undergo a regasification process. This process is comparable to that of LNG. Also similar to LNG is the dealing with boil-off gas from the liquid hydrogen. This gas is used to power the system in order to minimize losses. The system requires a set of converters, inverters and batteries to regulate electric power coming from the fuel cell.

Advantages

High efficiency - Above 20% load, fuel cells have a virtually equal energy efficiency. What this means is that even when the fuel cells are subjected to a low load - which is not expected - they provide a high conversion rate of energy.

Technically similar - Storage of liquid hydrogen bears many similarities to LNG, with similar sized tanks.

No emissions - Does not emit any tank-to-propeller greenhouse gasses.

Disadvantages

H2 Purity - The fuel cell requires high grade purity hydrogen, according to ISO 14687-2 a hydrogen purity of 99.97% is required.

Storage - Liquid hydrogen is the most challenging fuel to store, mainly due to its extremely low storing temperature. Because of the increased insulation standards, the storage tank is expected to have a 20% volume increase compared to the required fuel volume. A minimum of 10-30% of hydrogen needs to remain in the tank, similar to LNG. As this configuration consumes 7.300 m3 of hydrogen per fueling cycle, it will result in a total tank volume of roughly 10.600 m3. The size of the liquid hydrogen tanks is so such that it becomes almost undesirable to implement on the vessel.

> Ammonia

Option 2 is a drive-train that powers the vessel using ammonia in a spark-ignite dual fuel internal combustion engine. This drive-train design is mostly dominated by the regulations for gas fuelled ship installations. The overall system has an on-board efficiency of 43%. The energy density of ammonia and methanol are somewhat similar to LNG and therefore no major differences in tank volume are expected.

Storage - A total of 3.421 ton of ammonia needs to be stored in order to comply with the operational profile requirements. This leads to a total volume of approximately 5.260 m3 required including the space needed for insulation systems and leftover ammonia. Following the DNV-GL rules for classification, the ammonia will be stored in five 1.100m3 tanks under a pressure of 17 bar, each able to store approximately 750 tons of liquid ammonia. The DNV-GL rules for classification also restrict the locations of the cargo and service tanks. The service tank must be positioned on deck and have a venting system installed so direct venting of fuel gasses can be executed in case of emergency’s. The cargo tank can be installed below deck but must be positioned at least 760 mm from the hull for inspection access.

Drive train details - Ammonia is first vaporized and heated, after which 70%-volume is inserted into the engine and 30%-volume goes to the ammonia cracker for hydrogen reforming. The hydrogen is required for co-combustion, due to the poor combustion properties of ammonia. The 70%-volume ammonia and 30%-volume hydrogen mix results in a 96%-weight ammonia and 4%-weight hydrogen mix. Because the ammonia is mixed with the resulting hydrogen, a full hydrogen yield from the reformer is not required.

Exhaust - To comply with the IMO TIER III regulation, a Selective Catalytic Reduction (SRC) system needs to be installed located at the exhaust pipeline. This SCR system operates in the same way as the currently installed system on-board of the Sleipnir.

Advantages

No CO2 - Does not emit any CO2 but will require a Selective Catalytic Reduction system to minimize NOx emissions.

Storage - The energy density of ammonia and methanol are somewhat similar to LNG and therefore no major differences in tank volume are expected. It can be liquefied by storing it at -34 °C or at a pressure of 10 bar. Liquid ammonia has a volumetric energy density of 15.6 MJ/l.

Disadvantages

Fuel - Ammonia has a high resistance to auto-ignition and very slow combustion kinetics (also called low flame speed). These characteristics make the combustion of ammonia in an compression ignition engine challenging. That is why ammonia needs a fuel for co-combustion. For this study, hydrogen was chosen as co-combustion fuel.

Storage - Similar to LNG, all piping should be double walled and the complete fuel supply system has to be entirely separate from all other piping systems. All piping below deck must not only be double walled but also ventilated. This imposes serious technical demands when refitting existing vessels.

Exhaust - Internal combustion engines running on ammonia emit unburned ammonia in their exhaust gas, which necessitates the need for an SCR to comply with IMO TIER III regulations.

> Methanol

Option 3 is a drive-train that powers the vessel using methanol in a compression-ignite dual fuel internal combustion engine. This drive-train design is mostly dominated by the IMO regulations for low-flashpoint liquid fuels. The overall system has an on-board efficiency of 43%. The energy density of ammonia and methanol are somewhat similar to LNG and therefore no major differences in tank volume are expected. Methanol is easiest to store and does not require a large amount of cooling or expensive insulation and equipment.

Storage - A total of 4.100 m3 of liquid methanol under ambient pressure needs to be stored in order to comply with the operational profile requirements. As with ammonia, the DNV-GL rules for classification restrict the locations of the cargo and service tanks. The service tank must be positioned on deck and have a venting system installed so direct venting of fuel gasses can be executed in case of emergency’s. The cargo tank can be installed below deck but must be positioned at least 760 mm from the hull for inspection access.

Drive train details - Methanol is first vaporized and heated, after which 90%-volume is inserted into the engine and 10%-volume goes to the methanol reformer for hydrogen reforming. This hydrogen is used as pilot fuel, resulting in a 99%-weight methanol and 1%-weight hydrogen mix. Because the methanol is mixed with the resulting hydrogen, a full hydrogen yield from the reformer is not required.

Exhaust - Upon combustion of methanol, CO2 is released. In order to remain carbon neutral, a feedstock for the methanol is to be chosen that ensures total carbon footprint of well-to-propeller emissions are zero.

Advantages

Fuel - Methanol presents excellent combustion properties: despite its energy density is less then half of the LNG energy density (20.1 MJ/kg for methanol, 50 MJ/kg for LNG) it has a comparable octane number LNG (108 for methanol, 130 for LNG). This allows for a higher compression ratio and an increase in combustion efficiency. The performance of a engine running on methanol is directly comparably to the engines running on LNG.

Storage - Methanol is liquid at ambient temperatures and has the largest volumetric energy density of the three options, making the storage installation for methanol easier compared to liquid hydrogen and ammonia. There are no limitations regarding the storage capacity of methanol tanks since the fuel is a liquid at ambient temperatures.

Disadvantages

Fuel - Methanol has a low flash point and needs a pilot fuel to operate.

CO2 emissions - Because methanol is made from CO2 and hydrogen, methanol combustion will always emit CO2. Since one of the boundary conditions of the new drive-train is that system should have net zero well-to-propeller emissions in its life-cycle, the methanol combustion engine can not use diesel as a pilot fuel.

Storage & corrosion - Methanol has corrosive properties which need to be mitigated by storing it in stainless- or carbon steel tanks. The low flashpoint also imposes other restrictions on the tanks. Similar to LNG, these are mostly focused on the extra venting- and gas detection systems to prevent gas build up in the tanks. All piping should be double walled and that the complete fuel supply system has to be entirely separate from all other piping systems. All piping below deck must not only be double walled but also ventilated. All pre-systems should be placed on the deck whenever possible and should not be positioned in the engine room.

Economic Evaluation

> What is the most cost effective configuration?

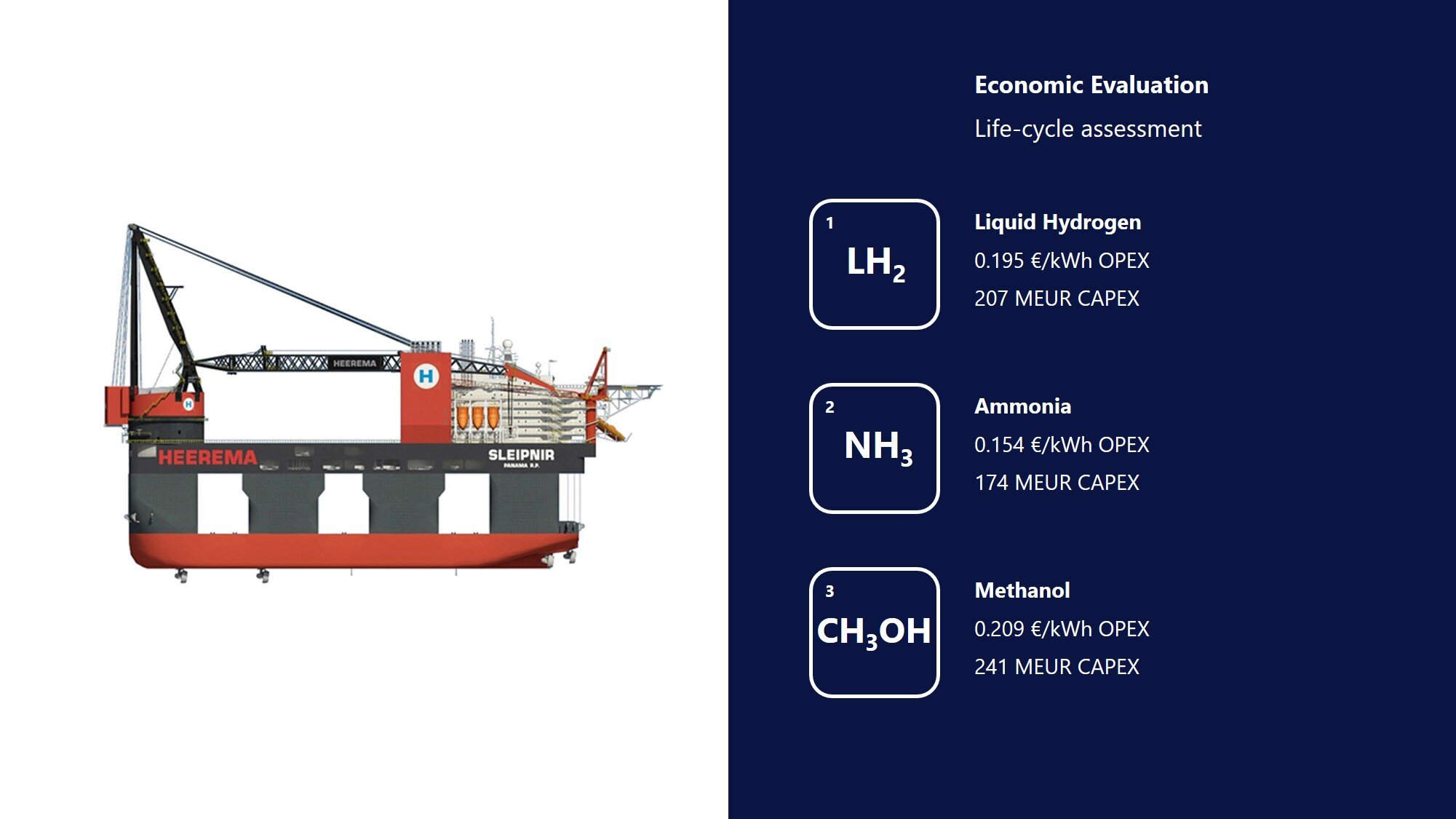

The ammonia fuelled drive-train is the cheapest configuration with a Levelized Cost of Energy (LCOE) of 0.154 €/kWh. Liquid hydrogen has a levelized cost of 0.195 €/kwh and methanol is the most expensive option at 0.209 €/kwh. Naturally, these levelized costs are subjected to assumptions that may significantly influence their outcome.

Fuel costs (OPEX) have by far the biggest influence on costs, between 71%-92% of total lifecycle costs (operating lifetime of 25 years). Ammonia and methanol are two of the most widely produced chemicals in the world, so the production costs of these fuels are expected to decrease little over time. Based on the price developments found in the literature, it can be expected that liquid hydrogen will eventually become cheaper than ammonia. This will happen when the production process is scaled up and economy of scale applies to liquid hydrogen.

It is expected a CO2 tax will make the business case for hydrogen carriers more attractive, which can be expected as soon as 2023 in the EU. A CO2 tax of €100 per mT is required to level the price of liquid hydrogen with current LNG on Sleipnir. It is expected liquid hydrogen will become cheaper than ammonia in the future, but this tipping point will only occur in 20 years time. With a CO2 tax of 75 €/ton, a drive-train running on LH2 will have the same LCOE as the current system. Methanol will become cheaper than the benchmark price at an CO2 tax of 150 €/ton, although it is unknown what a CO2 tax means for methanol considering a methanol-based combustion system still emits CO2.

(Commercial) Availability

> Liquid Hydrogen

Total global hydrogen use was about 115 Mt in 2020 according to the world nuclear association. The Sleipnir - a single vessel - would consume roughly 0.5% of this total. That means only 200 of these types of vessel would consume all of the world liquid hydrogen supply for hotel load only (!). This back of the hand calculation shows that production of (liquid) hydrogen needs to be scaled significantly.

> Ammonia

Ammonia is one of the most widely avilable chemicals in the world, together with methanol. No ammonia dual fuel engine has yet been made commercially available for marine operations. Wärtsilä is currently researching and developing ammonia as a fuel for both spark- and compressed ignition engines with field test expected in 2022 from Wärtsilä. MAN claims to have a 2-stroke Ammonia fueled marine engine installed in vessels by 2025. At the TU Delft, a feasibility study for an ammonia drive is currently being carried out by assistent professor P. de Vos.

> Methanol

Methanol is one of the most widely avilable chemicals in the world, together with ammonia. Experience with methanol combustion is limited however. Maersk has recently announced they plan to invest 1.4 billion dollar on methanol-fuelled ships. There are more maritime partners investing in methanol. The Green Maritime Methanol consortium is currently investigating the potential of methanol as well.

Health, Safety and Environment

> What is the best configuration in terms of health, safety and environment?

Each hydrogen carrier brings its own set of challenges - toxicity, flammability, corrosion - they can all be managed with the proper precautions.

A liquid hydrogen drive train 'wins' with regards to Health, Safety and Environmental (HSE) aspects, mainly due to ammonia toxicity and the low flash point of methanol. Unlike ammonia and methanol, liquid hydrogen is not a toxic substance, minimizing safety risks when handling the fuel. In addition, hydrogen has no local emissions (when used in a fuell cell) apart from water, while ammonia and methanol still produce NOx/N2O and CO2 emissions respectively. Hydrogen does have a higher flammability compared to the other dense hydrogen carrier, but this risk can be mitigated with the installation of proper ventilation systems.

Liquid Hydrogen

Liquid hydrogen has a very wide flammability range. This results in good combustion characteristics, as well as a higher potential flammability risk when leaked in non ventilated enclosed spaces. It is a non-toxic material resulting in a very low health hazard.

Ammonia

Ammonia is a toxic material that can be lethal when inhaled and form a environmental hazard when leaked in the ocean. Because of this fact, all piping should be double walled and the complete fuel supply system has to be entirely separate from all other piping systems (this is similar to LNG). All piping below deck must not only be double walled but also ventilated. These HSE restrictions consequently imposes serious technical demands when refitting existing vessels. Finally, internal combustion engines running on ammonia emit unburned ammonia in their exhaust gas, which necessitates the need for an SCR to comply with IMO TIER III regulations.

Methanol

Due to the low flash point of methanol, explosion hazard is the most important factor to consider in the design of the fuel supply line. In addition, methanol has corrosive properties which need to be mitigated by storing it in stainless- or carbon steel tanks. The low flashpoint also imposes other restrictions on the tanks. Similar to LNG, these are mostly focused on the extra venting- and gas detection systems to prevent gas build up in the tanks. All piping should be double walled and that the complete fuel supply system has to be entirely separate from all other piping systems. All piping below deck must not only be double walled but also ventilated. All pre-systems should be placed on the deck whenever possible and should not be positioned in the engine room.

Main Conclusions on Research Questions

> How can hydrogen be stored on board of the semi-submersible crane vessel?

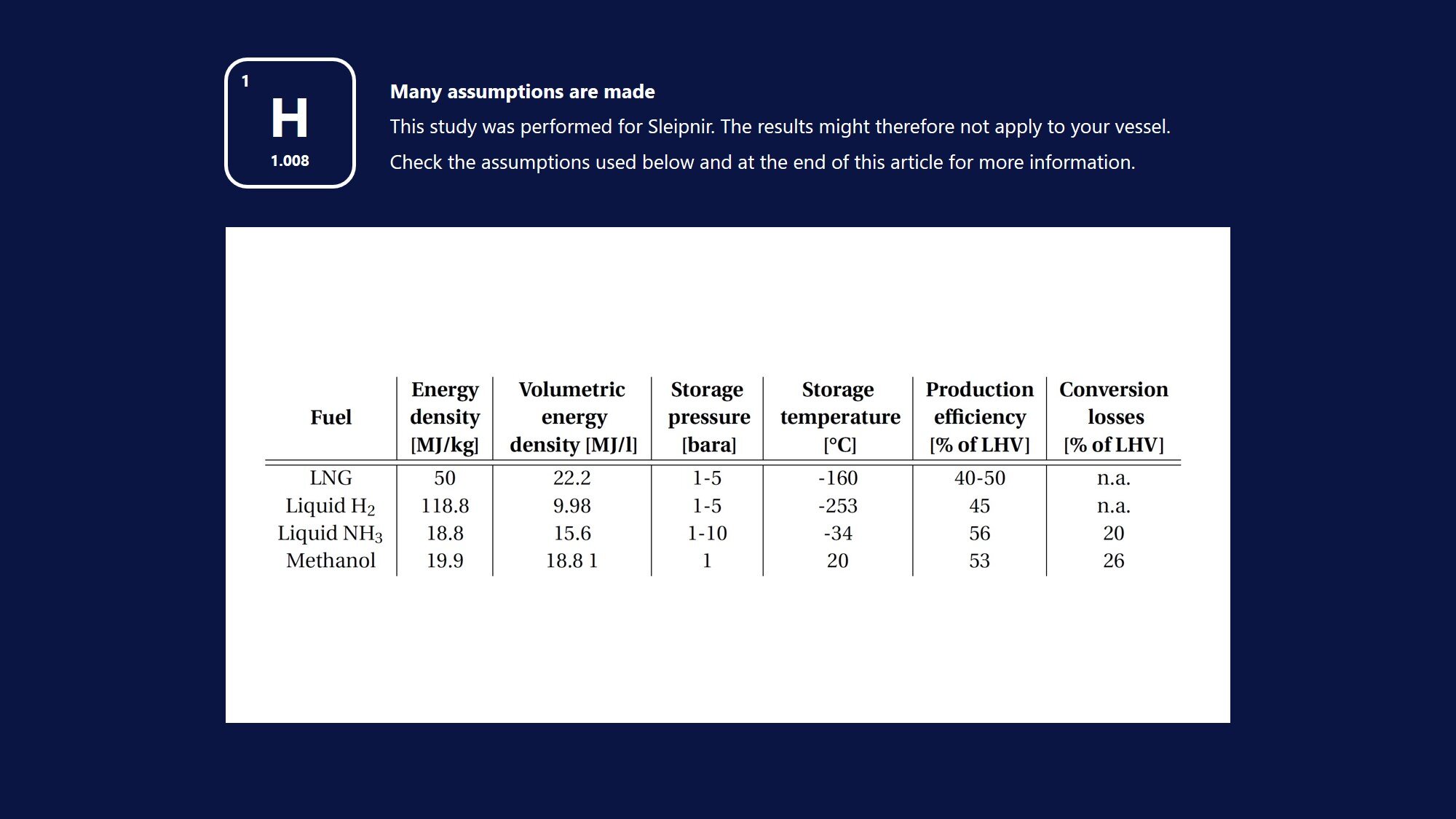

There are many ways to store hydrogen on board of a vessel. Due to the increasing demand for sustainable fuels, many new hydrogen carriers have already been tried and tested. However, most of these are still in the development phase and are not yet feasible within the boundary conditions set for this thesis. The literature study determined that liquid hydrogen, ammonia and methanol have the highest technical readiness level of all dense hydrogen carriers at this moment. These hydrogen carriers are therefore chosen for further elaboration in this study. The characteristics of these three are summarised as follows:

Liquid Hydrogen

- Liquid hydrogen stored at a temperate of -253°C. Consequently the storage tanks require a thick insulation layer resulting in a volume increase of 44% to minimize boil-off gas.

- With a volumetric energy density of 10 MJ/l when stored at -253°C, it is approximately 50% less dense then LNG and has the lowest energy density when compared to ammonia and methanol.

- Hydrogen is a non-toxic material resulting in a very low health hazard and no emissions when used in a fuel cell.

- Hydrogen has a very wide flammability range resulting in a higher potential flammability risk when leaked in non ventilated enclosed spaces.

Ammonia

- Ammonia is stored at a temperate of -34°C. To minimize boil-off gas, insulation is installed that results in a volume increase of 10%.

- Ammonia can be liquefied by storing it at -34 °C or at a pressure of 10 bar. Liquid ammonia has a volumetric energy density of 13 MJ/l.

- Does not emit any CO2 but will require a Selective Catalytic Reduction system (SCR) to minimize NOx emissions in order to comply with IMO TIER III regulations.

- Ammonia is a toxic material that can be lethal when inhaled and form an environmental hazard when leaked in the ocean. Consequently all piping below deck must not only be double walled but also ventilated.

- Due to a low flame speed, combustion in high RPM engines can be challenging so ammonia requires a duel fuel mixture with hydrogen co-combustion.

Methanol

- Methanol is stored as a liquid at ambient temperatures so no insulation systems need to be installed.

- Because methanol is made from CO2 and hydrogen, methanol will always emit CO2 at the vessel exhaust. The feedstock from which the methanol is made therefore needs to be from certified circular sources in order to ensure it is a CO2-neutral fuel.

- Methanol has the largest volumetric energy density of the three hydrogen carriers involved and is liquid under ambient temperatures, making storage the easiest of the three.

- It is a highly toxic and corrosive substance, necessitating the need for double walled and ventilated piping.

- Methanol has the best combustion characteristics of the hydrogen carriers and needs only a small volume of hydrogen as pilot fuel in a combustion engine.

> What technologies are applicable to convert the hydrogen into electrical power?

Within the scope of this study, the internal combustion engine and the fuel cell are investigated as feasible power units for the new drive-trains. Both systems have their advantages and disadvantages. Internal combustion engines can be used for all hydrogen carriers, fuel cells that can convert amammonia or methanol are still under development.

Fuel Cells have the advantage that they can convert chemical energy from a fuel into electrical energy without the need for combustion. Consequently, there are no harmful emissions produced as a by-product of the process. Within fuel cells, two types are studied: the Proton Exchange Membrane Fuel Cell (PEMFC) and the Solid Oxide Fuel Cell (SOFC).

PEMFC are new to the maritime industry and not yet widely used. Because of this, the systems are still very expensive and there is little experience with them within the industry.

The SOFC has the advantage of being able to run with high efficiency on different types of fuel. Unfortunately, this power unit is still under development and not yet available for marine use.

Internal combustion engines are a power unit widely used in the maritime industry for almost a century. It is a reliable technology that is cheap and low in maintenance. The biggest disadvantage of the engines is that it generates greenhouse gasses, NOx and other polluting emissions as a by-product of the process, depending on what fuels it run on.

> How do the dense hydrogen carriers influence the drive-train design of the semi-submersible crane vessel?

The ammonia and methanol drive trains do not differ much from the current LNG system. All three options have an internal combustion engine that runs on a mix of two fuels to get a good ratio of octane to cetane numbers so that an efficient combustion is achieved. The main difference is that the current LNG system uses MGO as pilot fuel and therefore has higher CO2 emissions than the proposed ammonia or methanol systems that use hydrogen for co-combustion or as pilot fuel respectively.

The hydrogen fuel cell drive train is very different from the current LNG system. Using a Proton Exchange Membrane Fuel Cell (PEMFC) requires a much more complex fuel handling system in order to generate a good stable electrical output.

Energy Efficiency In terms of on-board efficiency, the heat mass balance calculation shows that all three new options have an efficiency of around 43%. This is considerably higher than the current system and can be explained because the three new systems run at full load on their designed power output. If the combustion engines of options 2 and 3 are required to run at partial load, the efficiency will decrease to a similar efficiency as the current system. The fuel cell is less affected by this and will run at similar efficiency at at part load and full load.

Storage The last and biggest change in the drive-train design is the volume and type of fuel storage system. The current system runs on LNG which is stored at temperatures of around -160 °C. The storage of liquid hydrogen has many similarities to this system, but requires thicker insulation due to the lower storage temperature of -253 °C. This takes up more volume, and because hydrogen molecules are much smaller than LNG molecules, different materials must be used to prevent leaks. The estimated volume increase for liquid hydrogen storage is 20-44%.

The storage of ammonia and methanol is much less complicated compared to the current LNG system. Ammonia is stored under a much higher temperature (-34 °C). Tank volumes permitting, it can also be stored as a liquid at a pressure of 10-17 bar. This reduces boil-off gasses and energy losses through the storage system. Methanol has the most favourable storage conditions of the three dense hydrogen carriers. It is a liquid at ambient temperatures, so it does not require a complicated storage system. Therefore, more methanol can be stored per cubic meter compared to ammonia, LNG and liquid hydrogen.

Fuel Volume Due to the differences in volumetric energy density, a significant increase in volume is needed for the dense hydrogen carriers to store the required amount of fuel. Liquid hydrogen has the biggest difference with a required volume of 10.600 m3. Ammonia and methanol require 5.260 and 4.100 m3 respectively. This is still an increase compared to the LNG storage tanks but is considered to be feasible. The size of the liquid hydrogen tanks is so large that it becomes almost impractical to implement on the vessel.

Assumptions

> Time constraints

- A key boundary condition of this study is that the system has to be operational within 5 years. This time constraint significantly limits the use of several technical solutions that are not yet fully available, such as the solid-oxide fuel cell. If the boundary condition is extended by a few years, new technologies might become available, making ammonia-fuel cell and methanol-fuel cell configurations feasible. These drive train configurations have therefore not been considered in this thesis.

> Sleipnir vessel characteristics

- Sleipnir has 12 engines installed with 8 MW capacity each. The power generation of the Sleipnir is diesel-LNG electric, meaning that the internal combustion engines, powered by MGO and LNG, are driving alternators to generate electric power.

- Sleipnir hotel load is assumed to be 6.5 MW.

- Operations of Sleipnir should remain similar, meaning DP3 operations are required, similar tanking capacity, refueling roughly once every 7 to 8 weeks.

- Sleipnir has approximately 8,000 m3 of storage space for LNG and 11,000 m3 for MGO.

- More information on the technical and operation framework of Sleipnir can be found here.

> Hydrogen carriers

- All three carriers are considered carbon neutral from a shipowner’s perspective. In other words: it is assumed well-to-propeller emissions are carbon neutral. This means the use of green hydrogen and short-cycle carbon for methanol.

- Other dense hydrogen carriers (such as sodium borohydride, toluene or formic acid) are recognized as potential fuels for future shipping but have not been incorporated in this research. The reason for this is their relatively low technical readiness level, combined with the fact that it is Heerema’s ambition to fully prevent and reduce their carbon emissions by 2025. This makes it a requirement to use technologies that are available at scale now.

> Drive train configuration

- For the three hydrogen carriers, many drive train configuration options are available (see below). Only three drive trains - liquid hydrogen, ammonia co-combustion and methanol combustion - are investigated in this research.

- Proton Exchange Membrane fuel cell (PEMFC) and Solid Oxide fuel cells (SOFC) are identified as the most promising technologies by multiple market studies as well as DNV-GL with their fuel cell application study. For this research, only PEM fuel cells are considered as there are currently no commercially available SOFC systems available for maritime propulsion.

- Internal Combustion Engines (ICE) are well-know in the marine industry. Their reliability and low cost make it attractive to use in combination with a hydrogen carrier. Combustion engines have significantly lower standards on hydrogen purity and can consume a wide range of hydrogen carriers, including pure hydrogen and blends. However, since hydrogen fuel cells have a higher efficiency compared to combustion engines and do not produce any NOx emissions, pure hydrogen combustion is not evaluated in this research.

- For this research, only four-stroke engines are considered.

References

Gilles Hagen - Hydrogen Powered Propulsion for an Offshore Crane Vessel, TU Delft Repository

Sustainable Ships - Insights on Hydrogen

Heerema - Sleipnir

Heerema - Carbon Neutral Roadmap

Rogier Roobeek TU Delft - Shipping Sunshine