Get Ready for the Alfa Lift, an Electric-Hybrid Heavy Lift Crane Vessel

Battery pack details have not (yet) been disclosed!

Summary - The Alfa Lift, a new build heavy lift crane vessel owned by Offshore Heavy Transport, was recently launched and is on track to enter service by early 2022. The vessel features a 3,000 ton main crane, 10,000+ m² smart deck which can be fully submerged to a depth of 15 meters and a electric-hybrid battery system made by Kongsberg. Designed for the wind market, she can carry and install up to 14 monopiles or 12 jackets per voyage but can also be used for transport, installation or decommissioning of topside and subsea modules. Options exist for a further three vessels.

Get ready for the Alfa Lift

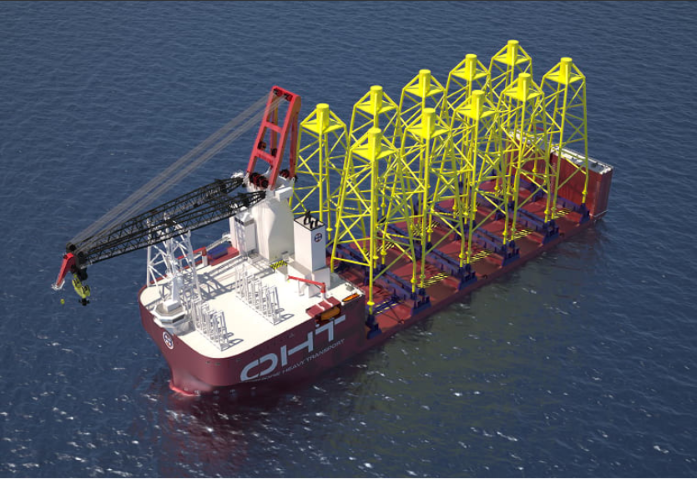

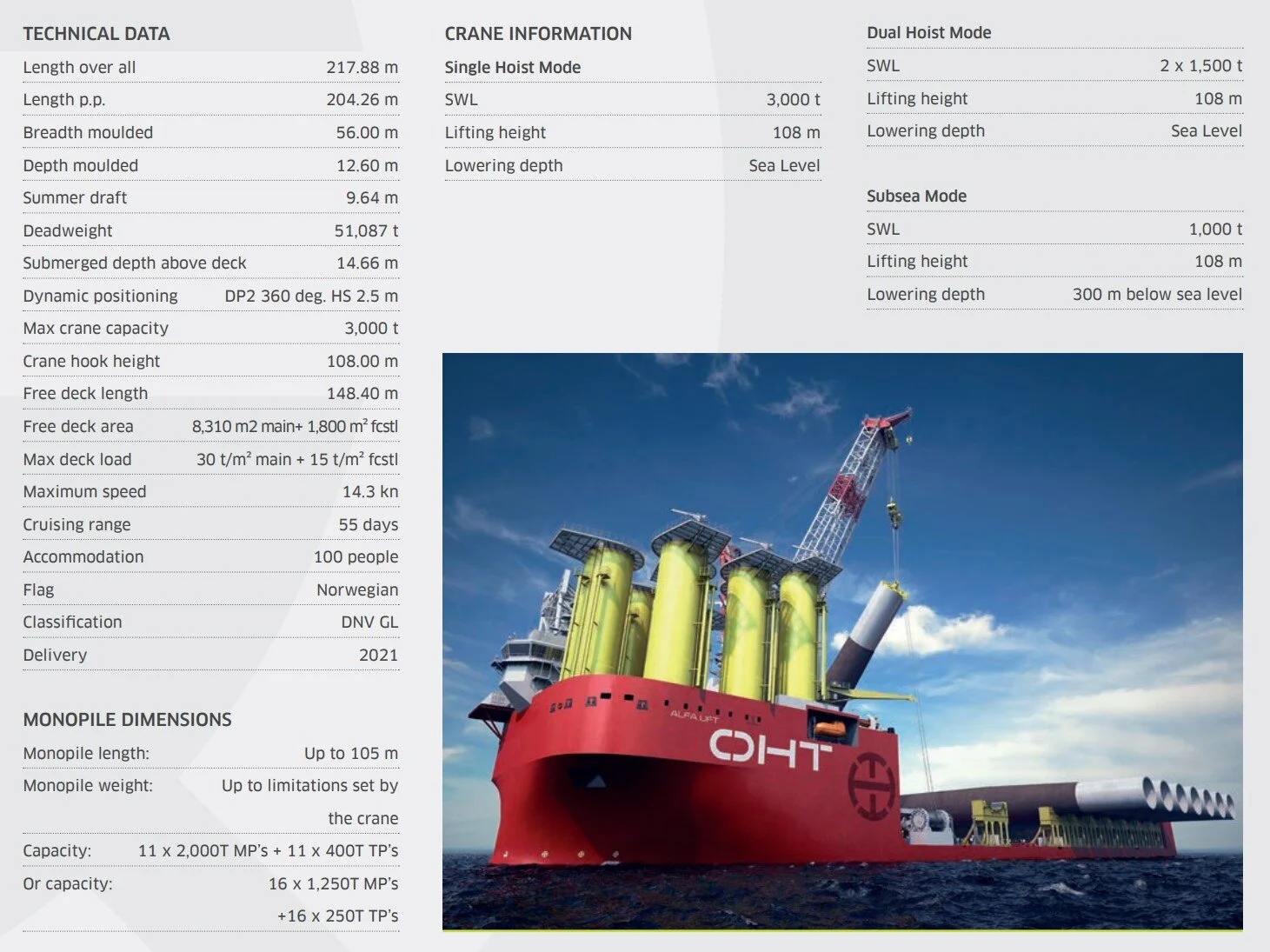

Early 2022, Offshore Heavy Transport (OHT) claims they will bring to market the largest and most innovative, custom-built offshore wind foundation installation vessel in the world: the Alfa Lift. She will feature a 3,000 t main crane, a 10,000+ m² ‘smart deck, capable of carrying and installing up to 14 XL monopiles or 12 jackets per voyage, and will be able to fully submerge the main deck to a depth of 14.66 m. At the time of writing it is unknown if the smart deck can be connected to Wi-Fi or that it is simply called smart because it can be submerged. Nonetheless the vessel boost numerous features to lower her impact on the environment.

Targeting the offshore renewables market, the vessel naturally has been developed to reduce emissions as much as practicably possible. In addition to the installation of exhaust gas scrubbers, the engines are Tier III compliant, and a battery package that will contribute to the reduction of the overall fuel consumption and resulting emissions.

The electrical package including battery hybrid power and energy management systems was provided by Kongsberg Maritime. It was announced in 2018 that they secured a $13 million contract to equip a new heavy lift crane vessel for Offshore Heavy Transport (OHT) with an innovative technology suite, including dynamic positioning, navigation, thruster control and automation systems.

Get ready for the launch

The Alfa Lift floated-out from its dry dock on Sunday the 28th of February. Mechanical completion of the vessel’s systems including steel outfitting will now continue while she is moored close to the dock. At the same time, slewing column and the A-frame have been completed in Rostock, Germany, to be installed in China after transport. All the parties involved are extraordinarily proud to have been part of this project, as is shown by their kind words.

Bjarne Birkeland, Head of Vessel Management for OHT said that “The vessel construction has progressed well despite these challenging times. We would like to sincerely thank everyone at CMHI who have worked with us closely to ensure that we have met the float-out milestone in a safe and timely manner, with work having continued through the recent Chinese New Year period. We are also grateful for seeing the quality Liebherr 3000 tons heavy Lift crane components being shipped from Liebherr’s facilities and look forward to seeing the crane installed on the vessel”.

Torgeir Ramstad, CEO of OHT added “This is an important milestone that brings Alfa Lift one step closer to entering service and helping to satisfy the ever-growing global demand for custom-built offshore wind installation vessels. We have no doubt that Alfa Lift will be a very busy vessel for many years to come”.

Mei Xianzhi, General Manager of CMHI added ‘The achievement of this important milestone could not be separated from the close teamwork between OHT and CMHI. Designed as an efficient vessel with one-stop service for both transportation and installation, Alfa Lift will surely become the favorite of the market for offshore wind installation vessels in the coming years. We look forward to delivery of the vessel and trust it will bring highly-efficient service to the end client in the near future’.

Get ready for the wind projects

The Alfa Lift will play a key role in the Dogger Bank project, following the announcement from SSE Renewables and Equinor regarding the financial close on Dogger Bank Wind Farm. According to Ulstein, who played a key role in the design of the Alfa Lift, she will transport and install all monopile foundations and transition pieces for each of the two 1.2GW phases of the project between 2022 and 2024.

“This is a significant milestone for all stakeholders to the projects, confirming that the conditional contracts awarded for the world’s largest offshore wind farm are now made effective. This includes OHT’s contract to transport and install the foundations, starting in 2022. We look forward to contributing to a successful project for SSE Renewables and Equinor” said Lars Kjuul Kristensen, Project Manager, OHT.

The question remains whether this vessel or the battery packs will become a staple design in the offshore wind market. Current trends seem to point in this direction however. Firstly, the offshore wind market continuous to grow and has recently been given a significant boost with U.S. President’s Biden plan to invest heavily. Secondly, clients and governments in the offshore wind market are aiming for net zero emissions during installation with more and more ambitious plans and shorter timescales. These trends, combined with the tremendous scaling and cost reductions currently ongoing in the battery market, show that hybrid vessels have a bright future ahead.

How does a hybrid vessel work?

New - Hybrid

A hybrid vessel has the same type of equipment on-board, that is the combustion engines, generators and switchboard. There is however a battery system added, which is connect to the switchboard. The battery system stores electric energy during normal operation. Upon a sudden failure of the diesel engine, or above a certain limit, the battery system can take over some or all power production, ensuring that the vessel can uninterruptedly continue its duty. Battery systems can generally provide virtually instantaneous power, which adds to the flexibility of the energy system in case of an emergency, increasing redundancy.

Current - Diesel Electric

A typical diesel-electric vessel works as follows. An internal combustion engine directly powers a generator (dynamo), turning mechanical energy into electrical energy. The electrical energy is routed to a switchboard, from which it is diverted to on-board systems that demand power. The power demand is determined by the energy consumers, for instance propulsion or deck equipment. If there is a sudden increase in power demand, the combustion engines will have to quickly provide this energy. There is a limit to how fast energy can be provided by diesel engines, which could result in blackouts on the vessel if power demand is limited by the power management system.

> Battery Functions

Generally speaking there are three types of functions a battery system can fulfill on-board a vessel:

Load leveling

Peak shaving

Spinning reserve

Load leveling and peak shaving are similar, as in that they moderate the load to a certain level. Load leveling makes sure the generator load remains constant continuously, while peak shaving only keeps the engine load within certain boundaries. This function potentially reduces the need to start up an additional engine. All functions save fuel, though it is usually the case that for larger vessels with larger generators spinning reserve applications preserve more fuel because one or more generators can be shut down. Running your generators more efficiently and having to use them less results in significant cost and fuel saving benefits.

References & More Stories

Mr. Sustainability - Insights on Batteries and Electrification

Kongsberg - Kongsberg to supply integrated technology for new heavy lift crane vessel

OHT - MV Alfa Lift

OHT - Alfa Lift is launched

OHT - Dogger Bank Confirmed – Financial Close Reached

Ulstein - Alfa Lift

Ulstein - Alfa Lift - The smart design for offshore wind installations

Join the discussion on the future of wind vessels on our community