Case studies | Find examples on decarbonization measures, costs and regulations to benchmark your business case

How to decarbonize your ship - battery hybrid + varying engine load

This case study also examines a general cargo ship with an auxiliary engine of 116 kW that is outfitted with a battery to make it a ‘battery hybrid’ while at berth. Again the battery pack powers the ship for several hours while idling or moored and is recharged using the auxiliary engines. This time however, engine load is varied in different loading scenarios to determine the impact of different operational profiles on the business case.

How to decarbonize your ship - general cargo ship with battery hybrid

This case study examines a general cargo ship with an auxiliary engine of 116 kW that is outfitted with a battery to make it a ‘battery hybrid’ while at berth. The battery pack powers the ship for several hours while idling or moored and is recharged using the auxiliary engines. Cost savings generally occur with an average engine load below 50%, but are mostly dependent on engine maintenance costs, spares and consumables as well as total battery pack costs.

How to decarbonize your ship - Large Fishing Trawler

This is a case study on how to decarbonize a fishing trawler - the Jacobus Maria - using shore power, battery hybrid EES and biofuels. 20% CO2 reduction is achieved, half of which stems from the use of biofuels (HVO). The hybrid battery pack is economically not feasible with the assumptions used and the operational profile. The Jacobus Maria has 1 MW installed engine capacity. Total cost would be at least €1M. 10% CO2 reduction can be achieved with approx. €50k.

Inside a Battery Container

The Corvus BOB (Battery On Board) is a standardized, class-approved, modular battery room solution available in 10-foot and 20-foot ISO high-cube container sizes. The complete system comes with battery, monitoring system, HVAC , TR exhaust, plus firefighting and detection system. The plug and play battery room simplifies integration into any system integrator’s power management system on board a ship. The battery cells have passive thermal runaway protection, and are type-approved according to DNV.

Maritime Battery Forum with Syb ten Cate Hoedemaker

During the lunch and learn, current forum Director Syb ten Cate Hoedemaker will exchange knowledge and experience from the usage of batteries within the shipping and offshore industries. You will learn which batteries will suit your vessel, plus discover the costs and payback for different operational modes. Which battery suits your vessel, your needs, your operational profile? This is the key question discussed in this lunch and learn with Maritime Battery Forum.

Hydrogen Powered Propulsion for an Offshore Crane Vessel

This thesis performs a technical, economical and environmental feasibility study of three dense hydrogen carriers as a fuel to power the largest semi-submersible offshore crane vessel in the world – Heerema’s Sleipnir.

Get Ready for the Alfa Lift, an Electric-Hybrid Heavy Lift Crane Vessel

The Alfa Lift, a new build heavy lift crane vessel owned by Offshore Heavy Transport, is on track to enter service by early 2022. The vessel features a 3,000 ton main crane, 10,000+ m² smart deck which can be fully submerged to a depth of 15 meters and a electric-hybrid battery system made by Kongsberg.

Webinar - Kongsberg Hybrid Solutions

A webinar on hybrid propulsion systems for offshore giving an introduction to a selection of our hybrid battery solutions and the advantages they offer.

The Big Friendly Hybrid Giant

The North Sea Giant, a Norwegian offshore construction vessel, is the first DNV class-approved ‘hybrid’ DP3 vessel with three batteries on-board that have a total capacity of 2.034 kWh. The batteries have been installed in an upgrade and serve the purpose of spinning reserve, peak shaving and load leveling. Since then, fuel consumption is reduced in all operational modes with over 2 million liters of diesel per year, saving up to 30% fuel.

Making the Impossible Possible

This blog sketches a vision on how to convert the largest crane vessel in the world - Sleipnir - owned by Heerema Marine Contractors, to a zero-emission vessel. Several promising carbon reduction measures are combined which are technically viable and based on matured technology including electrification and BES, solar panels, synthetic fuels, CCS and possibly hydrogen combustion.

Amazing Power of North Sea Giant

North Sea Giant is amongst the largest and most advanced subsea construction vessels ever built. North Sea Giant is an efficient multi-purpose vessel with supreme deck and crane capacity, alongside a unique power system. Her propellers and thrusters are tailor made for delivering a wide variety of demanding marine operations in deep and ultradeep waters.

How the North Sea Giant saves two million liters of diesel every year

The North Sea Giant saves two million liters of diesel every year. It has installed three battery packs and a distribution system from Wärtsilä, which will dramatically reduce fuel consumption. The North Sea Giant is one of the world's largest construction ships, and was the first vessel in its class to have a hybrid system installed on board.

LFP Battery Fire Hazard by FM Global

This video shows the potential fire hazard of an 83 kWh Energy Storage System comprised of Lithium Iron Phosphate batteries. The ESS had an overall electrical capacity of 83 kWh and ≥ 95% state-of-charge. No protection systems were active. Three heaters plus a propane pilot flame were installed to ensure vent gas ignition (!). The results from this test may not be representative of other LFP based systems.

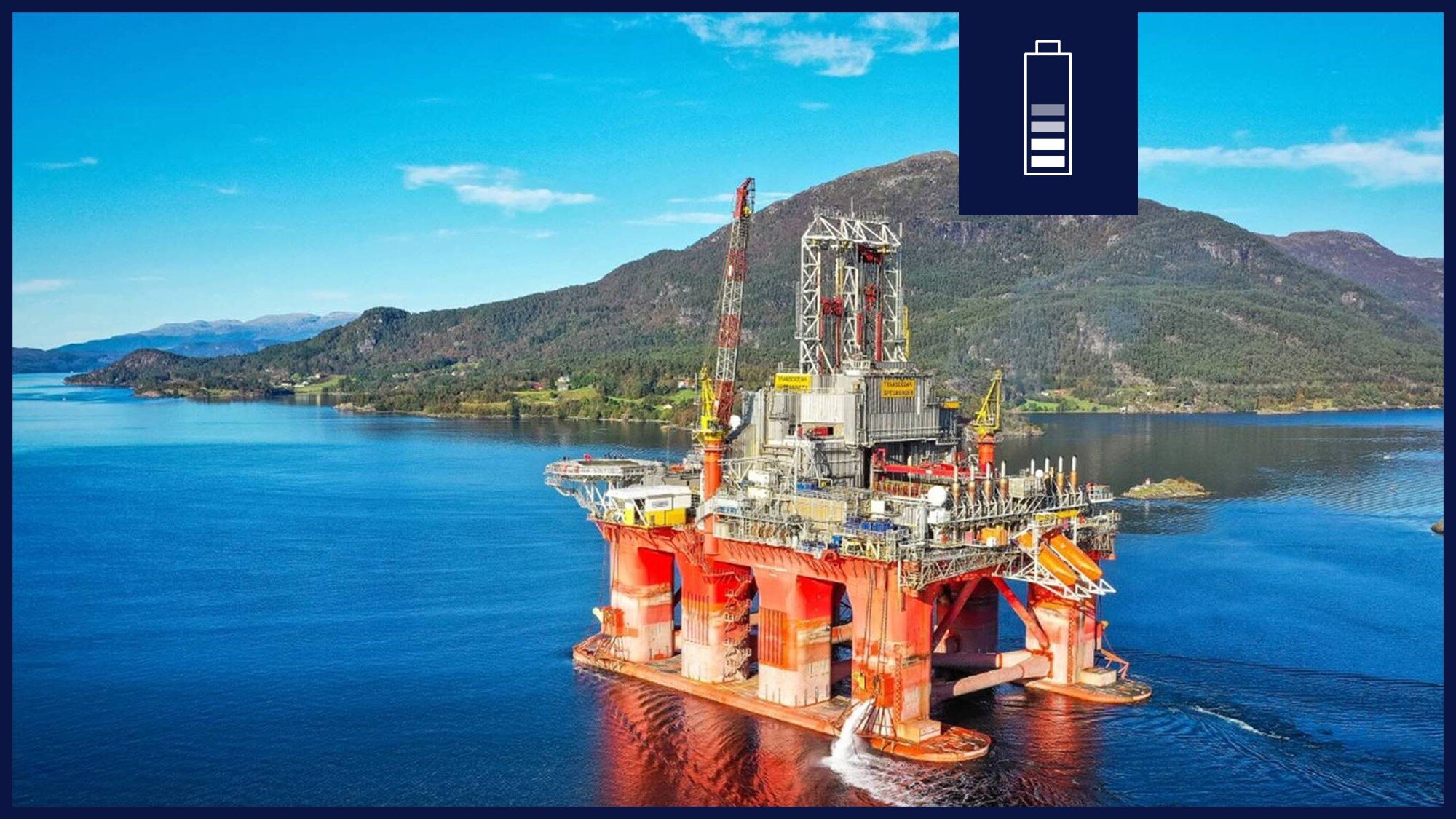

Transocean Spitsbergen goes Hybrid

In April 2019, the Transocean Spitsbergen successfully and sagely installed an electric Energy Storage System (ESS) of 5.6 [MW] on-board. This allowed the semi-submersible drillship to run in hybrid mode during DP3, reducing fuel consumption by about 15%. Economic incentives were provided in the fuel-clause and by the Norwegian NOx Fund.